Global Experts in Industrial Hazard Protection

There’s not a perfect word that encapsulates everything Fike offers, so “consultancy” is the best and fastest way for us to say: We are here to help in any way we possibly can. But Fike is much more than just a consultant – rather, we are a partner who can offer end-to-end solutions for most problems.

Explosion Consultancy

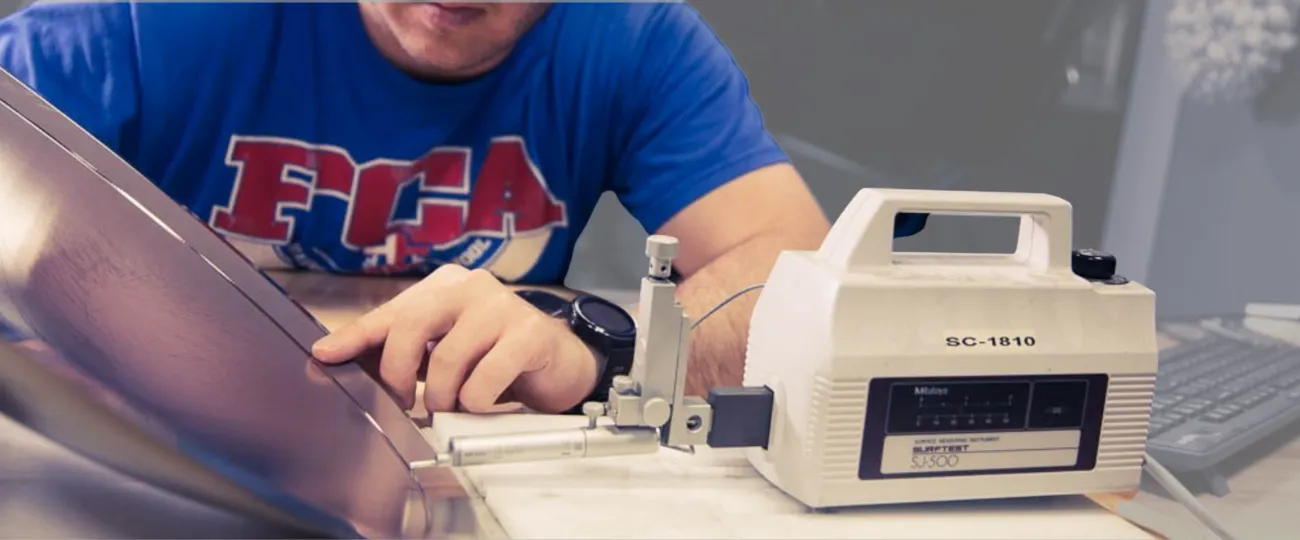

Dust Testing

Our on-site lab provides quick results to determine the explosibility values of your dust. Or if you’ve already performed dust testing, we can help analyze the data.

Risk Assessments

Walkthrough of your facility to identify hazardous areas and solutions, ensure compliance with codes and standards such as NFPA 660, and keep your employees safe.

Explosion Prevention

Identify methods of reducing the risk of ignition, many of which cost nothing such as improved housekeeping, process improvements, and more.

System Guidance

Count on Fike to help determine the most cost-effective solutions and prioritize where equipment is most needed, all within your budget and timelines.

Talk to an Explosion Protection Expert

Fire Consultancy

Hazard Analysis

PHAs, HAZOPs and DHAs are just a few of the types of analysis we can perform to identify special hazards that may require fast-acting fire protection systems.

Project Management

Let us handle the entire project, including ordering protection systems, managing contractors, working with local permits, and even performing factory acceptance testing.

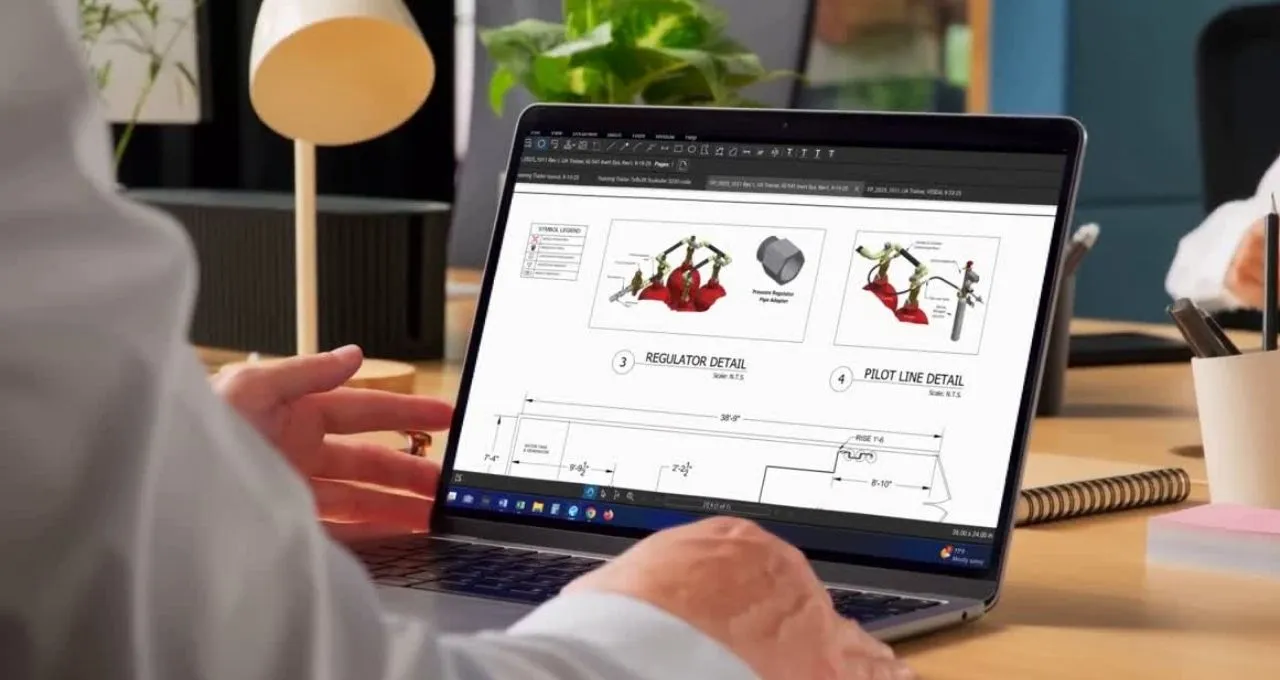

System Design

Offered for end users who need full design and flow calculation support and even to integrators who aren’t experienced with certain systems such as water mist suppression, for example.

Unique Applications

Comprehensive systems and service available for anechoic chambers, Ro-Ro ferries, automated storage and retrieval systems, and many other applications with special hazards.

Talk to a Fire Solutions Expert

Rupture Disc Consultancy

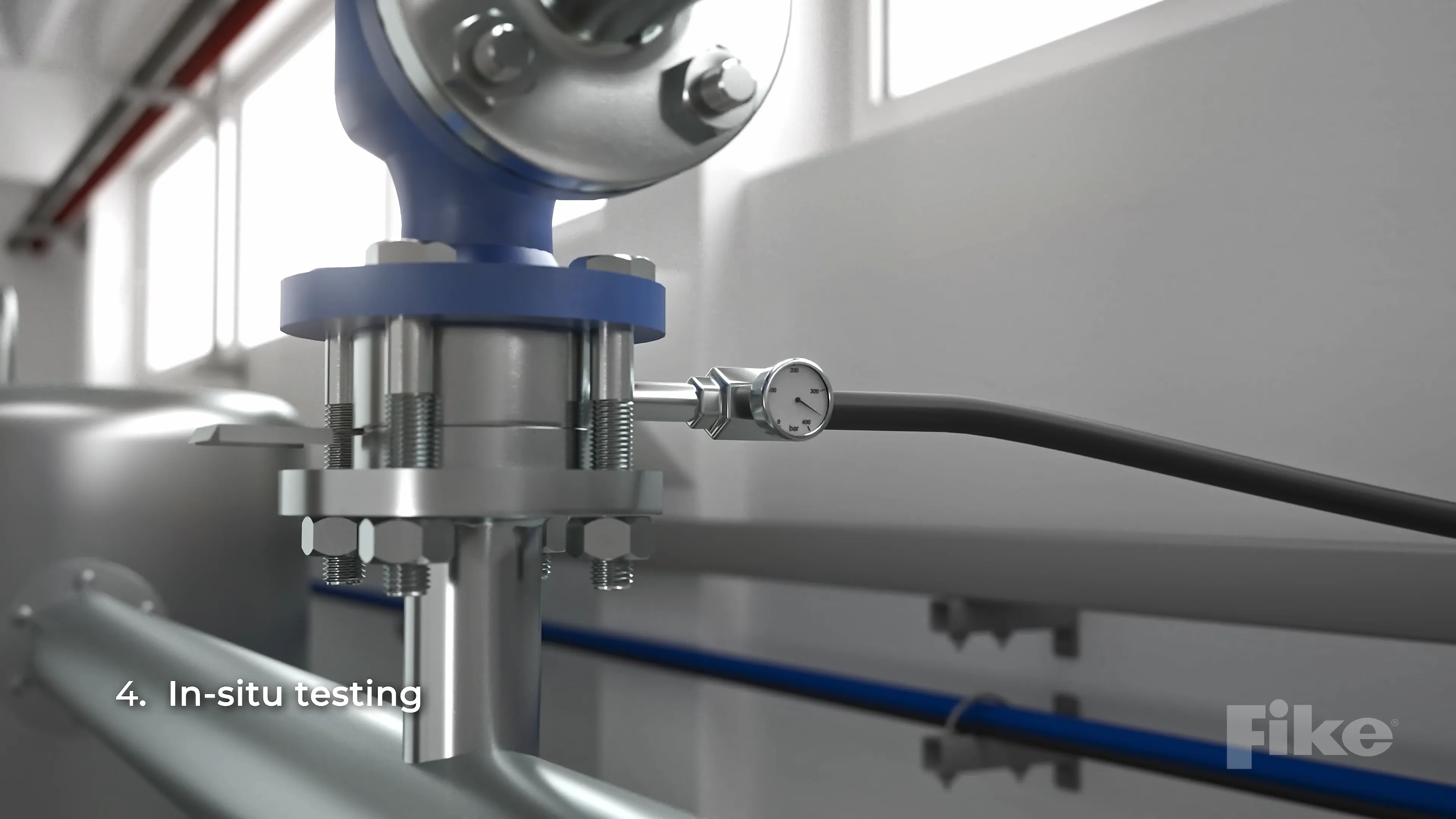

Disc Sizing & Selection

Ensure the perfect disc is produced by identifying the pressures, temperatures, pipe flange and ferrule sizes, type of media, vacuum and back pressures throughout your process.

Engineered Solutions

When pressure relief challenges fall outside of Fike’s standard rupture disc offerings, our team of engineers can work directly with you to design a product that meets your specific needs.

PRV Isolation

Analyze areas in your process in which rupture discs may be used in tandem with pressure relief valves to eliminate emissions, lower total cost of ownership, and more.

Site Survey

Identify cost-saving opportunities to improve your pressure relief system and reduce downtime by removing problematic rupture discs, consolidating rupture discs, etc.

Talk to a Pressure Relief Expert

Lithium-ion Battery & BESS Consultancy

BESS Protection Strategy

Determine the ideal protection methods (thermal management, explosion control, detection, etc.) to handle the effects of thermal runaway and to meet your unique business needs.

Li-ion Battery Testing

Understand the exact behavior of a thermal runaway event using your lithium-ion battery within the unique dimensions of your BESS, which is required for protection and UL9540A compliance.

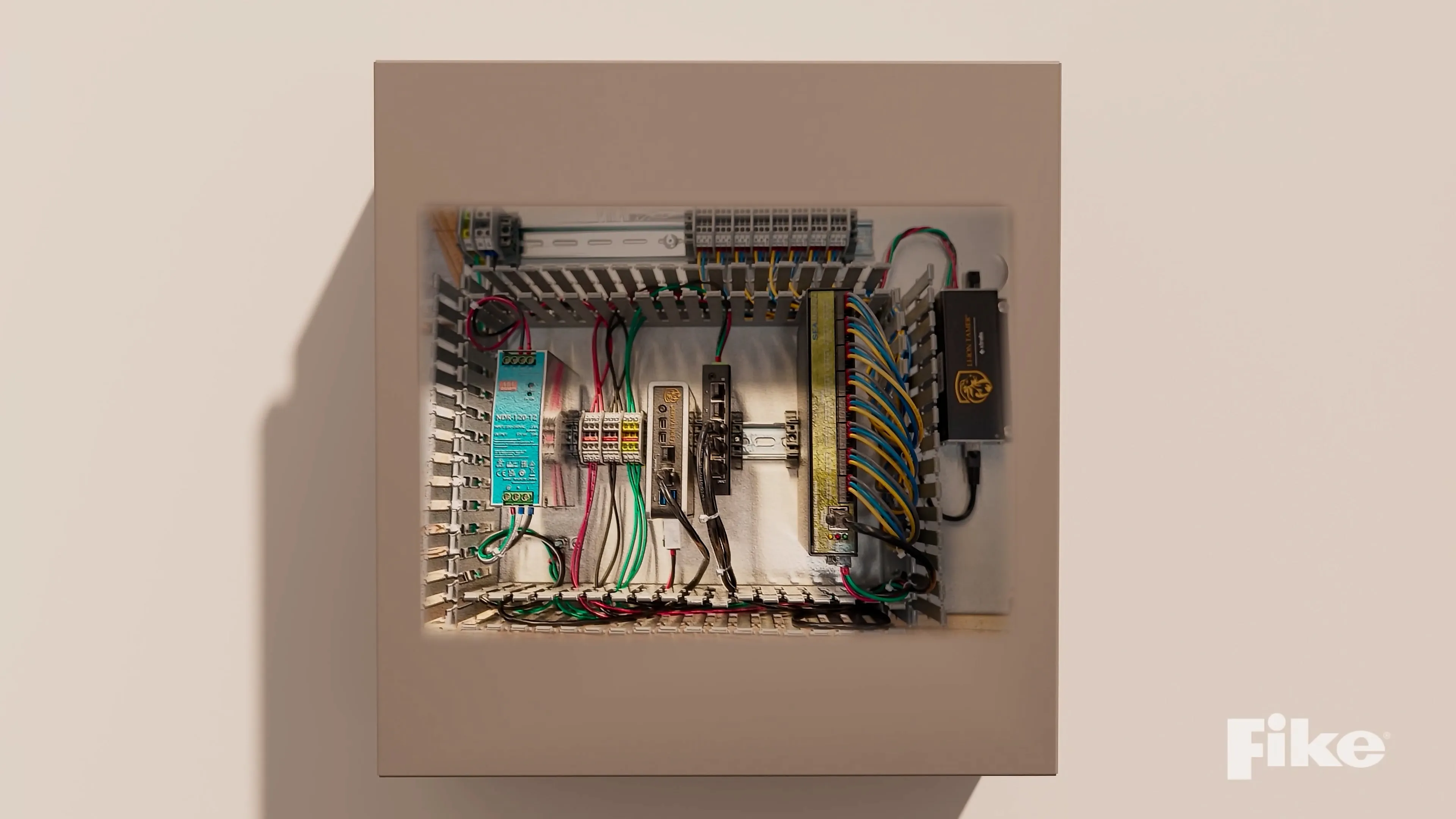

Custom Gas Detection

If your BESS requires early warning detection, we can help design an easy-to-install gas detection system using Li-ion Tamer or InfraSensing to save time and ensure proper installation.

General Li-ion Safety

While Fike specializes in BESS protection, we can also work with you to design solutions to protect li-ion manufacturing plants, warehouses and recycling facilities to ensure safety of workers.